3D Scanning & 3D Printing: Principles and Differences

Introduction

Ever wondered how the digital and physical worlds are merging more closely than ever before? With technologies like 3D scanning and 3D printing, the boundary between virtual designs and tangible objects is fading. But what exactly are these technologies, and how do they differ?

The Problem

Navigating the realms of 3D scanning and 3D printing can be confusing. Many people struggle to understand how these technologies work and how they can apply them in practical scenarios. This lack of understanding can hinder innovation and limit the potential for creativity in various fields.

Agitating the Issue

Without a clear grasp of 3D scanning and 3D printing principles, you're missing out on opportunities to simplify workflows, create custom solutions, and bring imaginative ideas to life. The gap in knowledge can feel like standing on the shore while others sail towards new horizons, leveraging these technologies to revolutionize industries.

The Solution

This article will demystify 3D scanning and 3D printing by exploring their principles, applications, and key differences. By the end, you'll have a solid understanding of how to harness these tools to bridge the gap between the physical and digital worlds.

What Is 3D Scanning?

3D scanning is the process of capturing the shape and appearance of a real-world object to create a digital 3D model. It involves collecting data on the object's geometry and texture, which can then be used for various applications.

Principles of 3D Scanning

At its core, 3D scanning involves measuring physical objects and translating those measurements into digital data. The primary methods include:

- Laser Triangulation: Projects a laser beam onto the object's surface and uses sensors to measure the reflected light.

- Structured Light Scanning: Projects patterns of light onto the object and captures the deformation of the patterns.

- Photogrammetry: Uses multiple photographs from different angles to reconstruct the object's shape.

- Time-of-Flight Scanning: Measures the time it takes for light to travel to the object and back to calculate distances.

Types of 3D Scanners

- Handheld Scanners: Portable and flexible, ideal for scanning large or immovable objects.

- Desktop Scanners: Generally used for smaller objects, offering high precision.

- Industrial Scanners: High-end devices used in manufacturing and engineering for detailed scans.

Applications of 3D Scanning

- Reverse Engineering: Recreating products without existing design data.

- Quality Control: Ensuring manufactured parts meet specifications.

- Cultural Heritage Preservation: Digitizing artifacts and structures.

- Medical Field: Custom prosthetics and orthotics design.

- Entertainment Industry: Creating models for movies and games.

What Is 3D Printing?

3D printing, also known as additive manufacturing, is the process of creating a physical object from a digital model by adding material layer by layer.

Principles of 3D Printing

3D printing transforms digital designs into physical forms:

- Additive Process: Builds objects by adding material rather than subtracting.

- Layer-by-Layer Construction: The object is constructed in successive layers dictated by the digital model.

- Material Versatility: Uses a range of materials, including plastics, metals, and ceramics.

Types of 3D Printing Technologies

- Fused Deposition Modeling (FDM): Melts and extrudes thermoplastic filament.

- Stereolithography (SLA): Uses a UV laser to cure liquid resin.

- Selective Laser Sintering (SLS): Uses a laser to sinter powdered material.

- Binder Jetting: Deposits a binding agent onto a powder bed.

Applications of 3D Printing

- Rapid Prototyping: Quickly creating models for testing and development.

- Custom Manufacturing: Producing personalized products.

- Medical Implants: Creating patient-specific implants and devices.

- Education: Hands-on learning with tangible models.

- Art and Design: Crafting intricate designs not feasible with traditional methods.

Key Differences Between 3D Scanning and 3D Printing

While both technologies deal with 3D models and physical objects, they serve opposite functions in the digital-physical workflow.

Fundamental Distinction

- 3D Scanning: Converts physical objects into digital models.

- 3D Printing: Converts digital models into physical objects.

Purpose and Usage

| Aspect | 3D Scanning | 3D Printing |

|---|---|---|

| Direction of Workflow | Physical to Digital | Digital to Physical |

| Main Use | Capturing existing objects | Creating new objects |

| Data Output | Digital 3D models (usually meshes) | Physical objects (from digital designs) |

Technology and Process

- 3D Scanning:

- 3D Printing:

Applications

- 3D Scanning:

- 3D Printing:

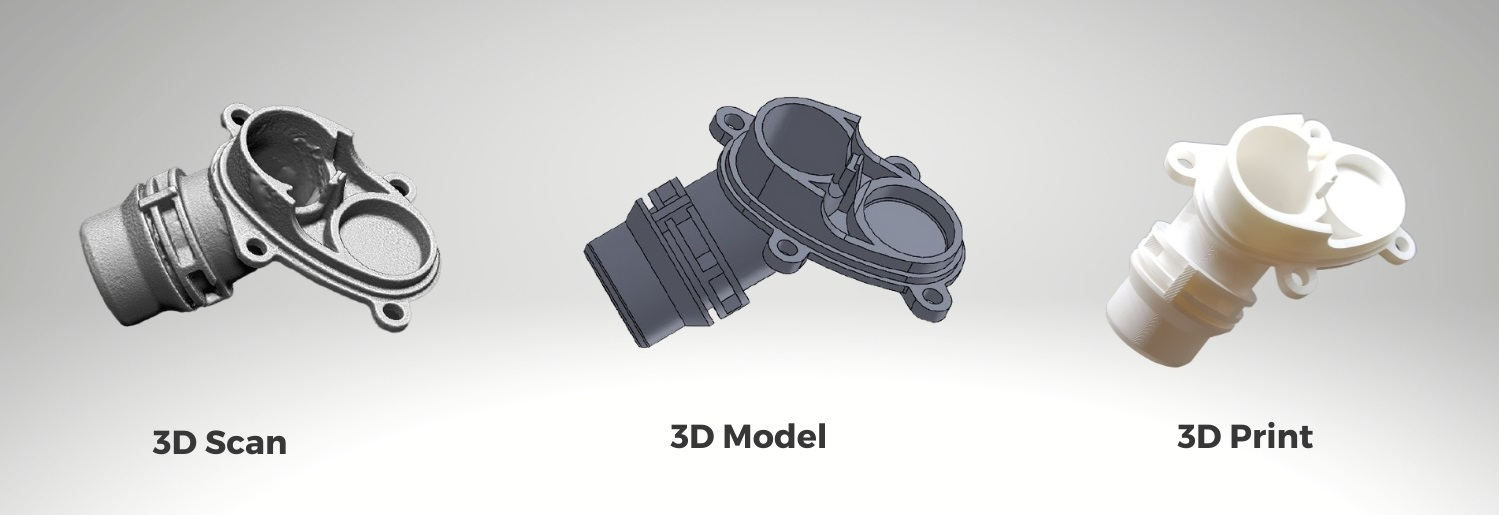

How They Complement Each Other

3D scanning and 3D printing often work hand-in-hand to create a smooth loop between the digital and physical realms.

Workflow Integration

- Capture: Use a 3D scanner to digitize a physical object.

- Modify: Edit the digital model as needed (e.g., improve design, fix defects).

- Produce: Use a 3D printer to create a new physical version.

Real-World Examples

- Manufacturing: Reverse engineer obsolete parts to produce replacements.

- Healthcare: Scan a patient's anatomy to create custom implants.

- Art Restoration: Reproduce damaged sculptures or artifacts.

Advantages and Limitations

Understanding the strengths and weaknesses helps in choosing the right technology for your needs.

Advantages of 3D Scanning

- Accuracy: High precision in capturing complex geometries.

- Speed: Faster than manual measurement methods.

- Non-Destructive: Doesn't alter or damage the object.

Limitations of 3D Scanning

- Surface Challenges: Difficulties with transparent or reflective surfaces.

- Cost: High-end scanners can be expensive.

- Data Processing: Requires time and expertise to clean and optimize models.

Advantages of 3D Printing

- Customization: Easily produce tailored products.

- Complexity: Can create intricate designs not possible with traditional manufacturing.

- Material Efficiency: Less waste compared to subtractive methods.

Limitations of 3D Printing

- Material Constraints: Limited by the materials that can be printed.

- Mechanical Properties: Printed parts may not match the strength of traditionally manufactured ones.

- Print Speed: Large or high-detail prints can take a long time.

Comparison Table: 3D Scanning vs. 3D Printing

| Feature | 3D Scanning | 3D Printing |

|---|---|---|

| Function | Digitize physical objects | Materialize digital designs |

| Primary Use | Reverse engineering, analysis | Prototyping, manufacturing |

| Equipment Needed | 3D scanner, computer | 3D printer, slicing software |

| Output | Digital 3D model | Physical object |

| Input | Physical object | Digital 3D model |

| Skill Requirement | Expertise in scanning and processing | Knowledge of printing and materials |

Choosing the Right Technology

Determining whether to use 3D scanning, 3D printing, or both depends on your specific needs.

When to Use 3D Scanning

- Capturing Existing Objects: When you need a digital replica of a physical item.

- Quality Inspection: Comparing manufactured parts to design specifications.

- Cultural Preservation: Digitizing artifacts for archival.

When to Use 3D Printing

- Creating New Designs: Bringing digital concepts into the physical world.

- Prototyping: Testing form, fit, and function of new products.

- Customization: Producing items tailored to individual needs.